Surface forces and friction between non-polar surfaces coated by temperature-responsive methylcellulose

Abstract

Graphical abstract

Materials and methods

Results

Shielding of hydrophobic groups due to aggregation and adsorption

Conclusions

Featured product

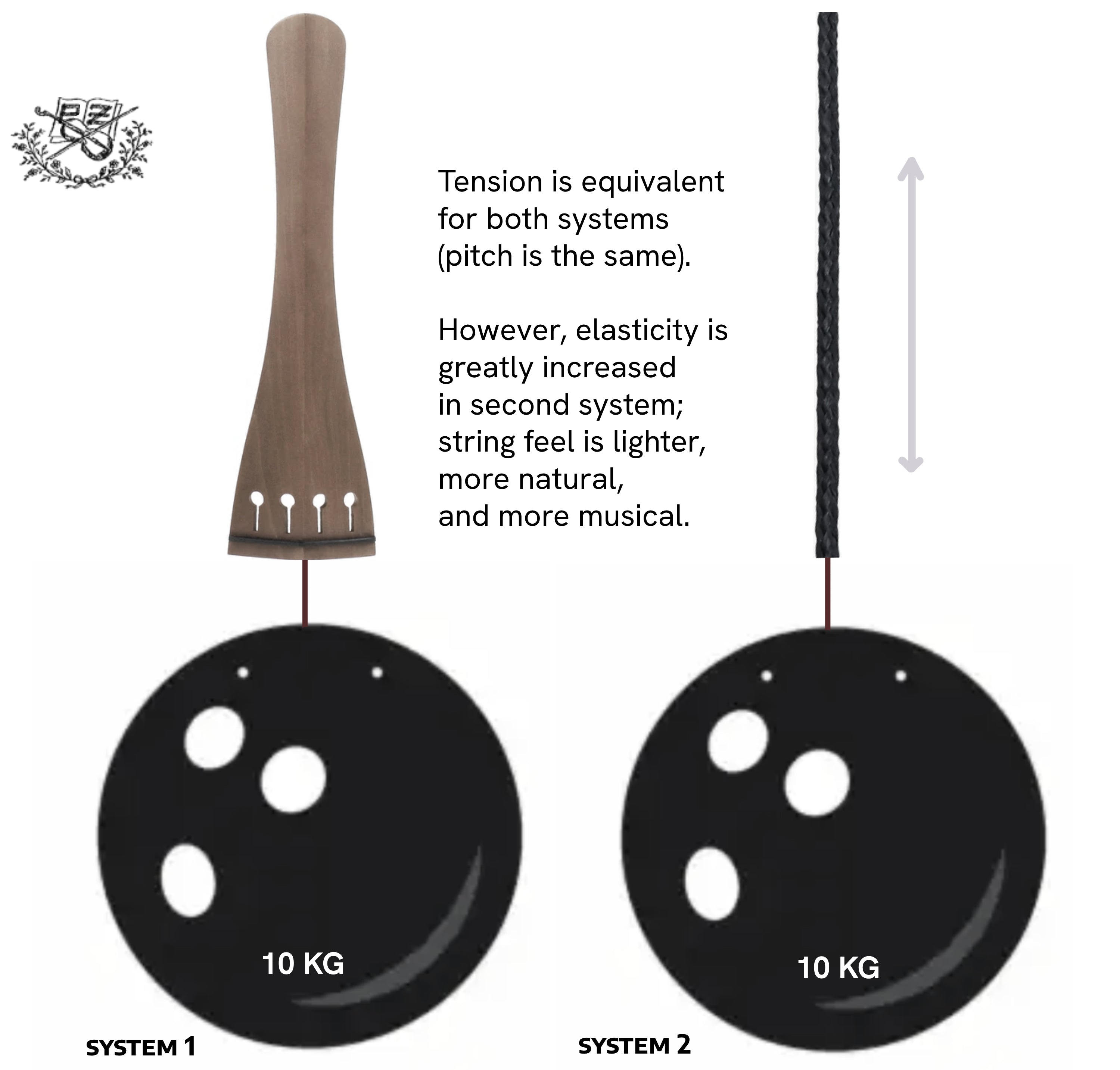

A liberated design utilizing woven Kevlar fiber. A component that expands overtones, resonance, sustain, vitality, responsiveness, and string independence - the Natural Tailpiece appeals primarily to common sense.

Softer string feel and a more natural playing action accelerates learning and technical mastery. The Natural Tailpiece essentializes the string suspension and tension mechanism, paring away the muting mass of plastic and metal that chokes and stifles your cello's innate vitality.

Tuning stability is also vastly improved - the tension of a single string does not influence any other string as it does when attached to a common floating plastic or wooden tailpiece. Each string terminates at a solid fixed point - the saddle - isolating the string's tension and unique harmonic and overtone profile.

Traditional silk wrap tidies up the appearance and adds an aristocratic feel; silk available in PZ Purple or Black.

Some considerations for your new tailpiece:

- Kevlar string exhibits a break-in period much like a steel string; a few hours of playing and tuning is a typical break-in period. However, once broken in, the Kevlar tailpiece will not respond to changes in humidity and temperature as does wood and steel, resulting in greater overall tuning stability.

- Geared tuning pegs are highly recommended with this tailpiece. Some cellists are adept at traditional peg tuning without fine tuners; most however will find geared tuning pegs necessary and ultimately a much more sensible and efficient peg arrangement. We are happy to install geared pegs for you at Peter Zaret and Sons Violin Shop in Cleveland, Ohio - a simple outpatient procedure we can do while you wait.

- Several equally effective methods for inserting the string ball end into the tailpiece loop are possible. You may wish for the Kevlar loop to capture the full ball end of the string, or wrap around the outer groove of the ball end (as shown in product photography). If you use strings with a loop end (gut strings etc.), please request a ball end to be shipped with your tailpiece free of charge. Ultimately, you will likely find that strings sit under tension more simply and elegantly and therefore last longer with the Natural Tailpiece.

Pickup available at 5767 Mayfield Road

Usually ready in 24 hours

Natural Tailpiece for Cello

Black / 4/4

5767 Mayfield Road

5767 Mayfield Road

Mayfield Heights OH 44124

United States